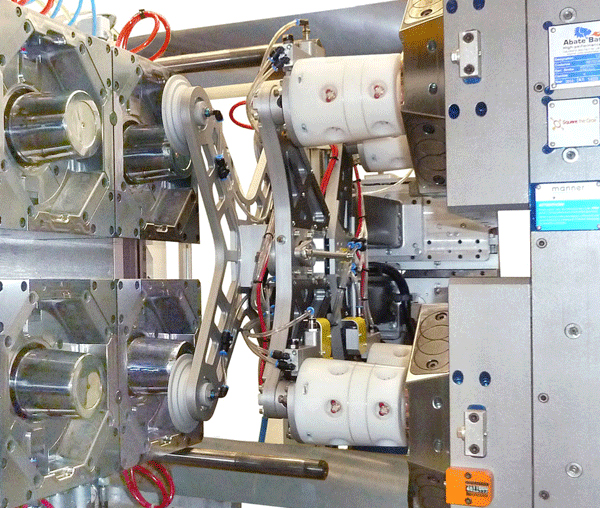

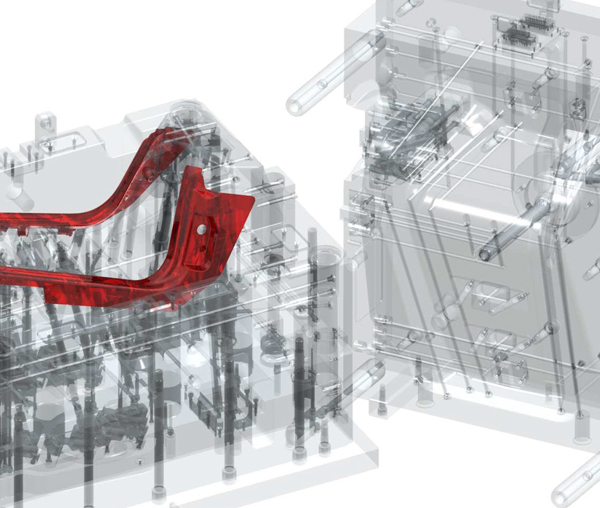

Star Automation Europe has been operating in Europe since 1989, It is a manufacturing and commercial structure taking advantage from the know-how of its Japanese head-office Star Seiki Co. Ltd, the world’s largest manufacturer of cartesian robots and automations for the injection moulding process.

Star Seiki Co. Ltd. manufactures 3000 robots per year and has installed more than 120,000 units worldwide in the last 30 years Star Automation Europe produces robots in all sizes (from 30 to 5000 tons) adapting the Japanese know-how to European standards. The result is a high quality product because of its original design the choice of components coming from the largest world-wide suppliers and the 36-years experience in the manufacturing of these specific robots are the best guarantee for the final user of their robots.